The success of our customer- and process-oriented management system.

Based on consistent implementation

and ongoing optimization.

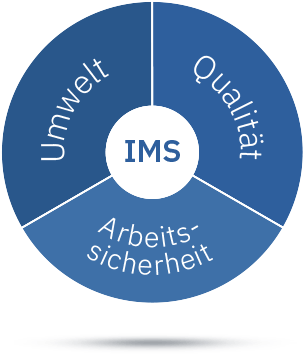

Our integrated management system (IMS) embraces all management processes to ensure quality, occupational safety and environmental protection.

Ongoing development and monitoring of the integrated system by trained IMS auditors further enhances the high quality, occupational safety and environmental standards. Regular certifications to 14001 (Environmental Protection) and 16949 (Quality) are evidence of this consistent alignment.